CerTrust Ltd. member of QTICS Group, whose portfolio of services for industrial robot systems is designed to facilitate their successful and orderly transfer, their commissioning and safe operation, even by assuming the manufacturer’s responsibilities as an Authorised Representative.

A great number of industrial robots are so-called “partly completed machines”, the operation of which can only start after the CE marking of the complete robot system. Other integrated machines and equipment are also part of the robot systems, the conformity of which and the proper management of the risks arising from their interactions are an integral part of the CE marking task and are also a matter for periodic safety checks during the operation of the robot systems.

Description of the service portfolio

Our compliance and safety services cover the entire life cycle of robot systems, including design, selection, procurement, construction, integration, handover- and in-service inspections.

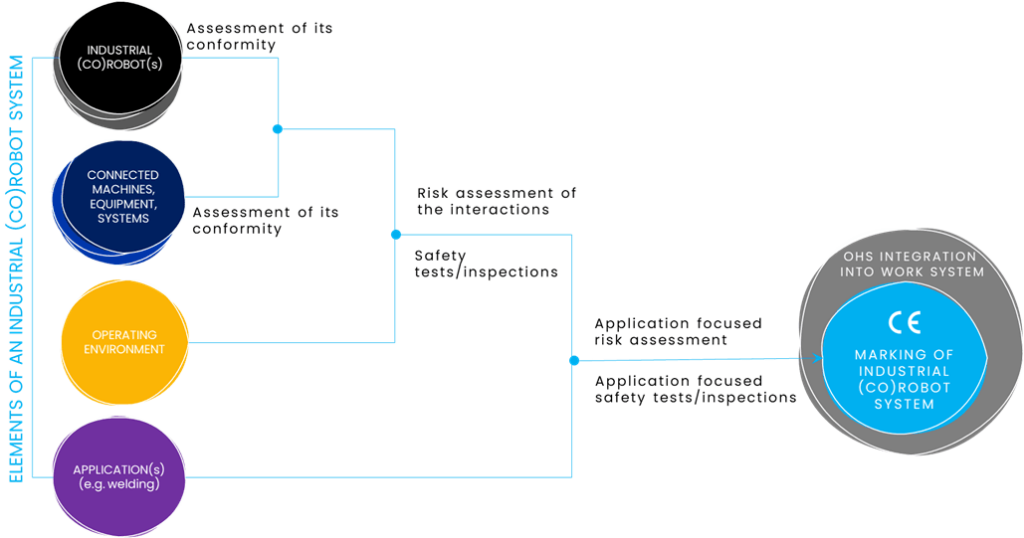

Industrial robot systems are combinations of robot(s) or, increasingly, collaborative robot(s) and other equipment integrated into the system (e.g. conveyors, specialized machines, safety equipment…), which have to cope with the effects of their operating environment and the technologies used (e.g. high temperatures, vibrations, presence of hazardous substances…), in addition to the legal requirements that apply to them. Consequently, during assessment, testing, and other related professional tasks of industrial robot systems one must always take into account at least the following aspects:

- conformity of the robot(s),

- conformity of any auxiliary machinery and equipment,

- risks and safety requirements arising from the interaction between the above and their operating environment,

- application-specific risks and safety requirements,

- cybersecurity vulnerabilities and protection against them,

- specificities of the complex work system.

This approach is summarised in the following figure:

These also constitute the foundation of our expert, consultation, and training activities, as well as the basis of our testing, inspection and certification activities.

Throughout CE marking and occupational safety related processes, the tasks to be carried out, the working methods to be used, the documentation requirements and the technical and safety requirements must be defined in line with applicable legislation and standards. The necessary competences, equipment, and other conditions could be specified based on the above.

In general, the framework and essential requirements of the conformity and safety of industrial robot systems are based on several EU legislation (e.g. MD, LVD, EMC, RED, EUCC…) and national legislation (occupational safety regulations…). Harmonised and other standards (e.g. EN ISO 10218-2, EN ISO 3691-4, EN 1175-1, EN 60204-1, EN ISO 13489-1, etc.), including national norms provide the minimum technical and safety level, the principals to be followed, as well as the methods to be applied. For industrial robot systems, in addition to the legislation, dozens of safety, functional and cybersecurity standards should be simultaneously considered.

These take into account design, safety and informational considerations, which form the basis of managing identified risks and of verifying the effectiveness of risk management.

What can our clients achieve with us?

- Lawful distribution of robotics products

- Successful and orderly transfer and commissioning of robot systems

- Continuous support by prepared and competent colleagues

- Management of business and occupational safety risks

Related services:

- Conducting the CE marking process

- Authorised representative tasks (assuming manufacturer’s responsibility)

- Standard conformity testing

- Risk assessment

- Validation of safety functions (SRP/CS)

- Cybersecurity assessment

- Technical-legal consultation

- Theoretical and hands-on training (CE marking of robots, robot systems – procedures, legal and technical requirements, manufacturer and operator tasks, safety engineering, occupational safety…)

- Review of conformity assessment documentation

- Conformity certification, EC Type Certificate

- Conformity/safety checks during takeover or installation (supplier checks)

- Pre-commissioning, periodic or special safety checks